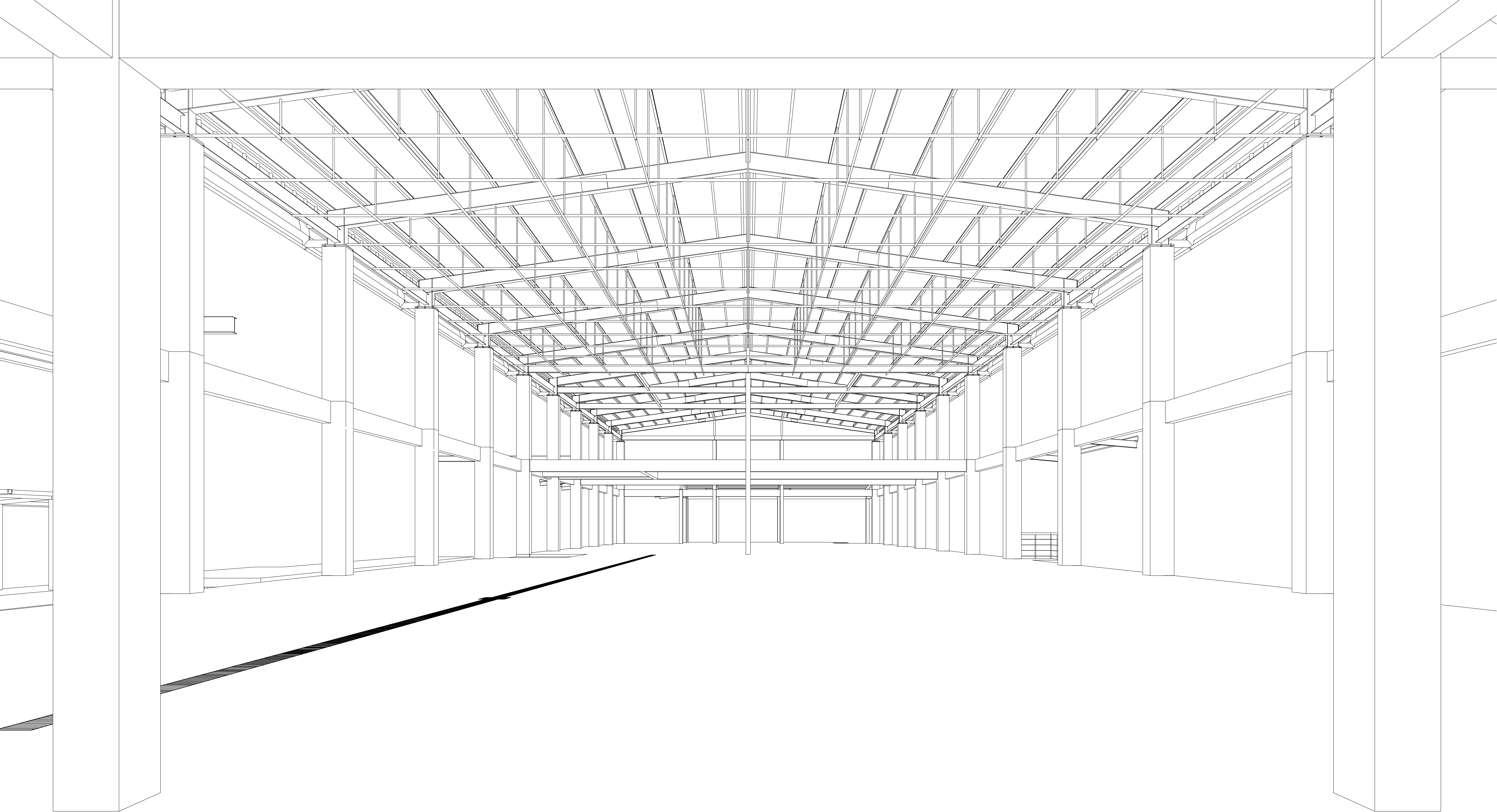

Production

of steel

STRUCTURES

We provide comprehensive prefabrication services for technological structures and installations as well as production, storage and process media supply systems.

Thanks to advanced technologies and automated production lines, we ensure optimal efficiency and the highest quality of steel structure production. We can prefabricate steel structures with maximum dimensions of 5.5 m x 5.5 m x 27 m and weight up to 60 tons.

We guarantee the highest level of safety and quality. Our structures meet the highest strength parameters thanks to multi-stage verification of the correctness of the work performed.

Our employees constantly improve their professional qualifications, and the quality control department, including the non-destructive testing (NDT) laboratory, ensures reliability.

Attention to EVERY detail

Prefabrication at OMIS begins with shot blasting, which can be carried out to Sa 3 standard depending on the project requirements.

This allows us to adjust the level of surface preparation to specific needs, guaranteeing its optimal quality and durability.

Our processes are monitored using ultrasonic, penetrant and magnetic particle methods, by certified controllers, as well as using non-destructive testing (NDT) methods such as X-ray testing.

.jpg&w=1920&q=75)

CERTIFIED WELDERS

The key element of our production is welding, which is treated with the utmost care and precision at OMIS.

Our team consists exclusively of certified welders. We use PULSE and TIME welding technologies,

and a highly qualified team, including International Welding Engineers and Inspectors (IWE, IWI), ensure the highest quality of welds.

Our welding is based on advanced Fronius devices and automatic welding stations, using qualifications 111, 121, 135, 136, 138 and 141, which ensures the highest quality, precision and efficiency of processes.

.jpg&w=1920&q=75)

Protection of steel structures

At OMIS, we use spray painting up to class C5, which provides the highest level of anti-corrosion protection in difficult conditions, such as the maritime industry or areas with high pollution.

These processes are supervised by our certified FROSIO inspector, which additionally guarantees quality and compliance with requirements.

We also offer fire-retardant painting and galvanizing as an additional or alternative method of protection. Painting is carried out using painting systems from recognized brands, guaranteeing durability and protection of the structure, while galvanizing is carried out by our trusted partners.

.jpg&w=1920&q=75)

Machines and Technological Equipment

Our plants are equipped with modern machines from renowned manufacturers such as FRONIUS, VOORTMAN, DURAL and DURMA.

We use advanced technologies for abrasive blasting, cutting, drilling, milling and precise bending of pipes.

Our rolling machines allow for rolling sheets with a diameter of up to 5 m and a thickness of 24 mm, and bending machines allow for bending sheets with a length of up to 6 m and a thickness of 30 mm.

.jpg&w=1920&q=75)

STRUMIS is a complete ERP system for production and information management. It is an ERP/MRP solution dedicated to companies in the steel construction industry.

With StruM.I.S we can precisely track and control production processes, which ensures high quality and efficiency. It also ensures full traceability of elements at every stage.

STRUMIS allows for full control over every stage of production, from planning and pricing, through material orders, to final assembly. This gives you the confidence that all project elements are monitored and implemented according to schedule.

The system automatically manages materials, tracking their consumption and availability. Features such as inventory management and sheet metal cutting optimization help minimize waste and reduce production costs, significantly increasing operational efficiency.

.svg)

STRUMIS enables ongoing monitoring of production progress, which allows for quick response to any deviations from the plan. The ability to track in real time provides transparency and facilitates decision-making.

.svg)

STRUMIS integrates seamlessly with popular CAD software such as TEKLA Structures, enabling easy import and management of 3D models. This simplifies the work of engineers, speeds up the design process and minimizes the risk of errors.

.jpg)

.jpg)

.jpg)

.jpg)